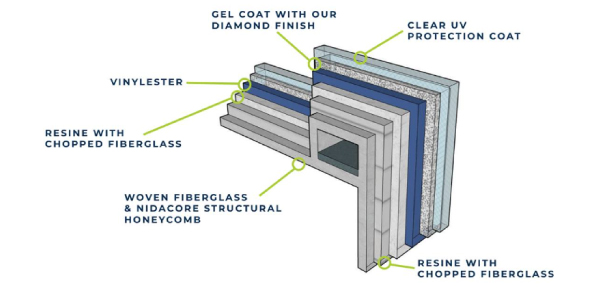

Cross-Section of Fiberglass Pool Layers

This diagram showcases the advanced multi-layered structure of our fiberglass pools, highlighting the materials and their roles in ensuring durability, strength, and aesthetics:

- Gel Coat with Diamond Finish: The outermost layer, providing a smooth, luxurious surface with exceptional resistance to scratches and fading.

- Clear UV Protection Coat: A protective layer that shields the pool from harmful UV rays, preventing discoloration and ensuring long-lasting vibrancy.

- Vinylester Layer: A premium resin layer designed to enhance resistance to osmosis and protect against chemical damage.

- Resin with Chopped Fiberglass: Adds structural integrity and flexibility, absorbing impacts to prevent cracking or deformation.

- Woven Fiberglass with Nidacore Structural Honeycomb: A core reinforcement layer combining woven fiberglass with a lightweight, honeycomb structure for superior strength and stability.

- Resin with Chopped Fiberglass (Base Layer): A foundational layer providing additional support and durability to maintain the pool’s structural integrity.

At Pools Premium, we take pride in crafting premium fiberglass pools through a meticulous and innovative manufacturing process. Every step is designed to ensure durability, precision, and customer satisfaction:

- Design and Engineering

Our expert engineers create state-of-the-art designs, integrating structural integrity, functionality, and aesthetic appeal. Each model undergoes rigorous testing and refinement to meet the highest standards. - Mold Preparation

High-precision molds are carefully prepared to ensure the perfect shape and finish for each pool. This step is critical for achieving the smooth surfaces and flawless lines that define our pools. - Gel Coat Application

A premium gel coat is evenly sprayed onto the mold, forming the outer layer of the pool. This layer provides a sleek, polished finish and acts as the first line of defense against wear and UV damage. - Vinylester Layer Application

To enhance water resistance and prevent osmosis, a layer of vinylester resin is meticulously applied. This step ensures long-lasting durability and chemical resistance. - Fiberglass Reinforcement

Multiple layers of chopped fiberglass and resin are applied using advanced spray equipment. This process creates a robust yet flexible structure capable of withstanding heavy loads and environmental stresses. - Structural Core Integration

For added strength, a core layer of Nidacore or similar honeycomb material is integrated into the pool walls. This ensures stability and reduces the risk of deformation. - Final Layers and Curing

Additional layers of fiberglass and resin are applied to achieve the desired thickness and strength. The pool is then left to cure under controlled conditions, ensuring a seamless bond between all layers. - Quality Inspection

Every pool undergoes a thorough inspection to ensure it meets our stringent quality standards. This includes checks for structural integrity, surface finish, and dimensional accuracy. - Finishing Touches

Once approved, the pool is carefully demolded, trimmed, and polished. Final details are added to enhance its visual appeal and functionality. - Packaging and Delivery

The completed pool is securely packaged and prepared for delivery, ensuring it arrives in perfect condition, ready for installation.

This process guarantees that every pool we manufacture is not only beautiful but also built to last, providing years of enjoyment and peace of mind for our customers.

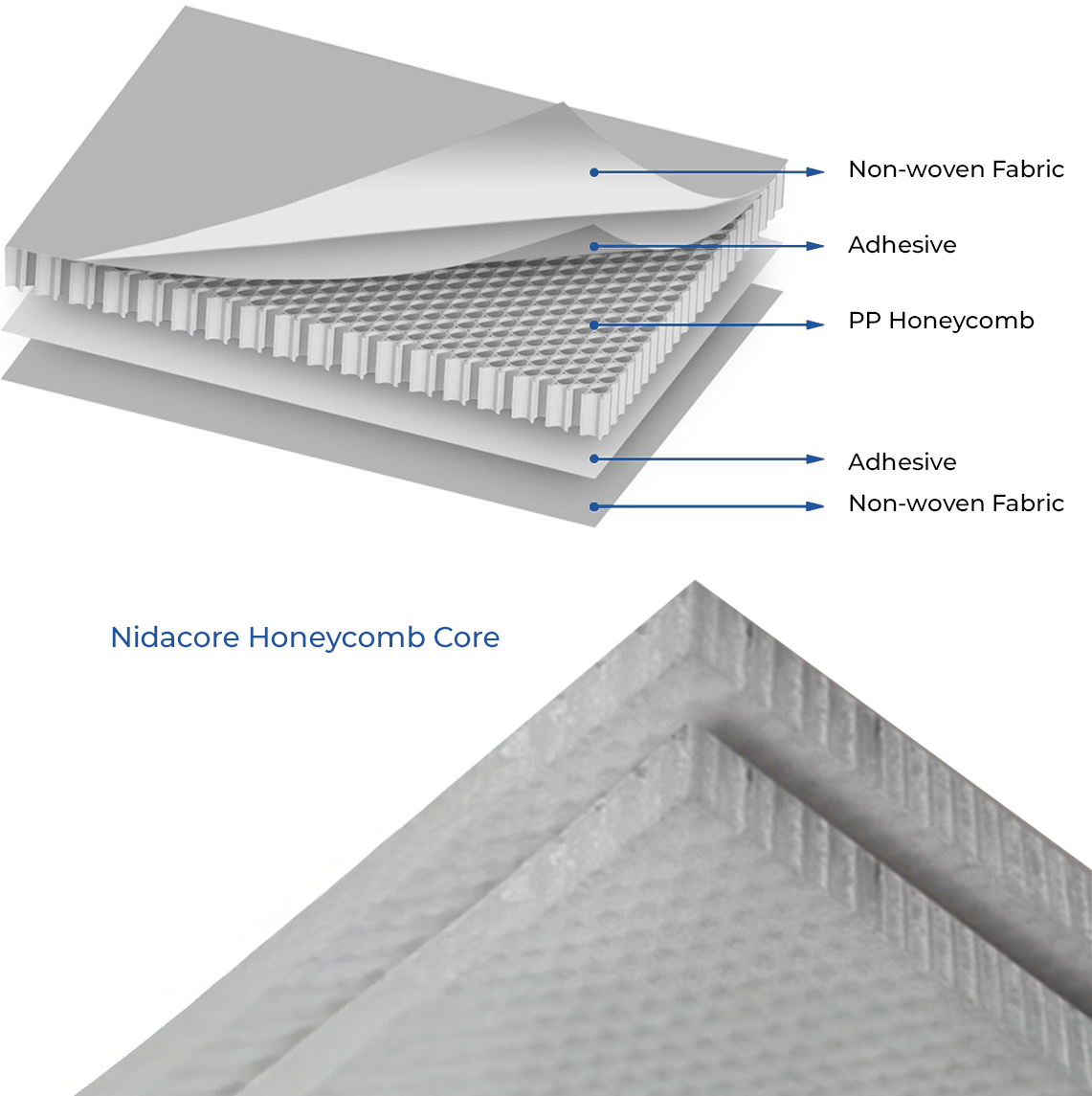

PP polypropylene honeycomb exhibits a unique cell structure. The core has 3 orientations vs. the 2 orientations common with other honeycomb, making its properties more uniform. Each cell has a tubular form and is inherently stable. PP polypropylene honeycomb is supplied with or without a non-woven polyester veil for better bonding. It is also supplied with or without a film barrier under the polyester veil to limit the amount of resin consumption.

Applications:

PP polypropylene honeycomb uses include sandwich panel cores, energy absorption and filtration media

Features:

• High strength to weight ratio

• Corrosion, fungi, rot, chemical

and moisture resistant

• Sound and vibration dampening

• Energy absorbing

• Thermoformable

• Temperature use to 180°F

• Recyclable

Additional layers of resin mixed with chopped fiberglass further enhance the pool’s resilience, enabling it to withstand challenging conditions without cracking.

Additional layers of resin mixed with chopped fiberglass further enhance the pool’s resilience, enabling it to withstand challenging conditions without cracking.

This signature feature gives the pool a glossy, eye-catching finish with a smooth and comfortable surface. Diamond Flakes technology also ensures a durable, low-maintenance coating.

Our fiberglass pools are crafted with precision and engineered for excellence, combining advanced materials and innovative techniques to create a product that is durable, low-maintenance, and visually stunning. Built to enhance your lifestyle, each pool reflects our commitment to superior quality and design.

Fiberglass pools are prefabricated, making installation faster and cleaner compared to concrete pools, which require extensive steel reinforcement and framing.

The durable materials reduce the need for maintenance and chemicals. Unlike concrete pools, they don’t require resurfacing.

Layered materials and advanced reinforcement prevent warping or damage, maintaining the pool’s shape under harsh conditions.

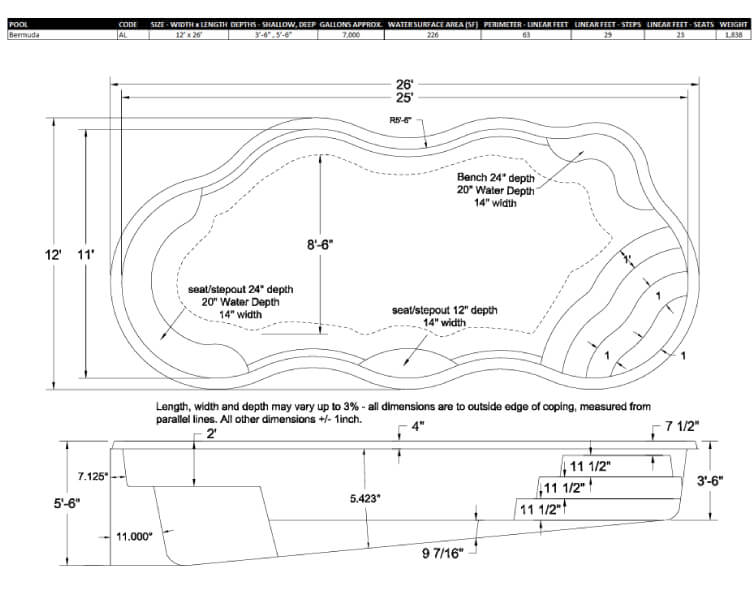

Each pool model includes detailed excavation plans to guide proper leveling and installation, ensuring precision and customer satisfaction.

We are dedicated to innovation, integrating advanced materials and manufacturing to deliver pools that set industry standards for beauty, durability, and maintenance.

WE WILL RESOLVE ALL YOUR DOUBTS